Table of Contents

The Importance of Watch Case Materials

In the world of custom watch manufacturing, choosing the right materials for your watch case is more than just an aesthetic decision—it’s a crucial factor that impacts both design and functionality. As a watch manufacturer looking to create a distinct timepiece, understanding the strengths and limitations of various materials is essential for delivering a product that reflects your brand’s identity while meeting the practical needs of your customers. Whether you’re working on an OEM or ODM watch, the material of your watch case plays a central role in shaping not only how the watch looks, but how it performs over time.

For any custom watch manufacturer, balancing design and durability is key. Should you go for the timeless appeal of stainless steel, the lightweight advantage of titanium, or the modern elegance of ceramic? Each material brings its own benefits, but the decision ultimately depends on your target audience and the type of watch you’re aiming to produce. Whether you’re focusing on luxury, everyday wear, or something in between, the right material can elevate your watch design to the next level.

To explore more about the different material options for watch cases, dials, and straps, check out our comprehensive guide on watch material options.

Common Materials Used in Watch Cases

When it comes to custom watch manufacturing, the material you choose for your watch case can significantly influence both its appearance and performance. Each material offers unique qualities, from durability to weight, and even how the watch feels on the wrist. Let’s explore some of the most popular materials used by watch manufacturers to help you make an informed decision for your custom or OEM/ODM watch designs.

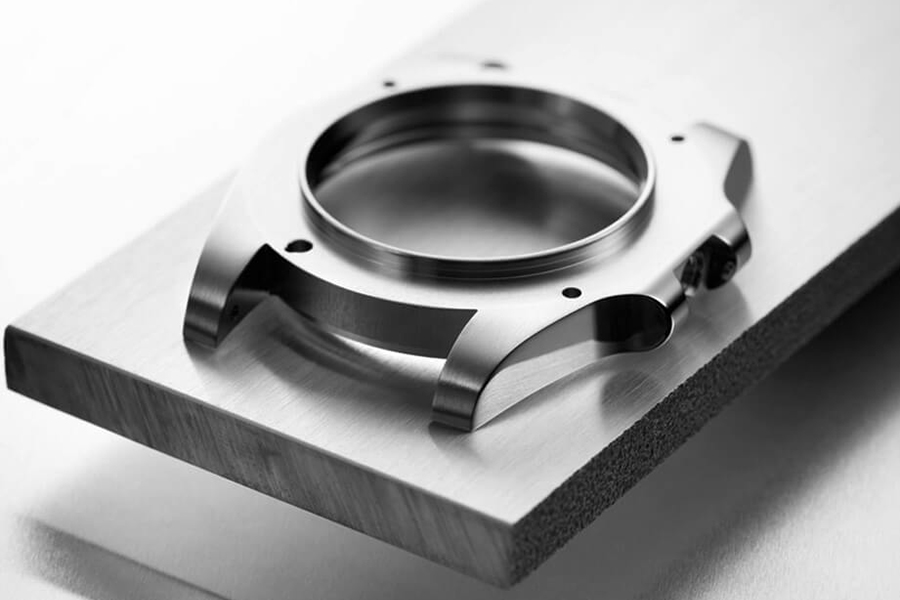

Stainless Steel

Stainless steel is by far one of the most common materials used in watchmaking, and for good reason. It’s durable, resistant to corrosion, and has a timeless appeal that works across both casual and luxury watch designs. Stainless steel cases are also versatile, offering finishes like polished, brushed, or even a combination of both, which gives manufacturers more freedom in creating unique designs that reflect your brand’s style.

Titanium

For brands looking to offer something a little more premium, titanium is an excellent option. This material is not only lighter than stainless steel, but also stronger, making it perfect for watches designed for active lifestyles or outdoor use. Titanium is also hypoallergenic, which adds an extra layer of appeal for customers with sensitive skin. However, it’s important to note that the lightweight nature of titanium can sometimes make a watch feel less substantial, so it’s crucial to balance functionality with customer expectations.

Ceramic

Ceramic has gained popularity in recent years, especially in high-end and fashion-forward watches. Known for its scratch resistance and modern, sleek look, ceramic cases give watches a bold, distinctive style. While ceramic is incredibly durable, it’s also more brittle than metals like stainless steel or titanium, meaning it can crack under extreme pressure or impact. As a watch manufacturer, it’s essential to weigh these factors when deciding if ceramic fits your brand’s design goals.

Brass

Though not as widely used as the materials above, brass brings a unique, vintage aesthetic to custom watch designs. Over time, brass develops a natural patina, which gives each watch a unique, worn-in look that many collectors and vintage enthusiasts love. However, brass is prone to oxidation, which can alter the appearance over time, so it’s best suited for brands aiming for a retro or industrial feel.

Gold and Precious Metals

For brands in the luxury segment, gold or other precious metals like platinum are timeless choices that symbolize elegance and wealth. These materials are typically reserved for high-end watches due to their price and status appeal. While they offer unmatched prestige, they also require more maintenance and care. Choosing gold or platinum is about aligning your material choice with a brand that values exclusivity and refinement.

By carefully considering these materials, you can create a custom watch that not only looks stunning but also aligns with your brand’s identity and functional needs. Each material brings its own benefits and challenges, so it’s vital to think about who your watch is for and how it will be used.

Impact on Design: Aesthetics, Weight, and Feel

The material you choose for a watch case doesn’t just determine its durability—it also profoundly affects the overall design and feel of the watch. From how the watch looks to how it sits on the wrist, each material brings unique characteristics that influence customer preferences and brand perception.

Aesthetic Appeal

Different materials offer distinct visual effects, allowing watchmakers to experiment with various finishes, textures, and styles. For example, stainless steel can be polished to a mirror-like shine for a classic, formal look or brushed for a more contemporary, understated appearance. Titanium, on the other hand, tends to have a matte finish that exudes modern sophistication, making it a popular choice for brands wanting a sleek, minimal design.

For brands aiming for luxury, materials like gold or platinum add an element of exclusivity and opulence. These precious metals not only elevate the overall aesthetic but also send a clear message about the watch’s premium nature. In contrast, ceramic cases offer a bold, modern look that’s often favored in high-fashion watches, with their smooth, glossy surfaces giving a futuristic feel to the design.

The choice of material can also influence color options. While metals like stainless steel and titanium come in neutral tones, materials such as brass offer a more rustic, vintage look with its evolving patina over time. Ceramic, too, allows for a wider range of colors, from sleek black to bright, eye-catching hues, enabling brands to create statement pieces.

Weight and Wearability

Material weight is a critical factor when it comes to wearability. Titanium, for example, is much lighter than stainless steel, making it an ideal choice for customers who prefer lightweight watches, especially for everyday wear or during physical activity. However, lighter materials might not provide the same sense of robustness that customers associate with more substantial timepieces.

On the other hand, stainless steel and gold cases tend to have more heft, offering a solid, premium feel on the wrist, which can be particularly appealing in luxury or statement watches. The weight of the watch can also influence comfort—heavier watches may feel more secure and substantial, while lighter watches provide ease of wear over long periods.

Material Feel

The tactile experience of a watch case is often overlooked but is a key aspect of how customers perceive the quality of a watch. Ceramic is known for its smooth, cool texture, which enhances the experience of wearing a high-fashion or tech-forward design. In contrast, titanium provides a more industrial, rugged feel that appeals to active or outdoor watch enthusiasts.

Brass, with its raw, unpolished surface, creates a more vintage or handcrafted feel, making it a great choice for heritage-style timepieces. Meanwhile, stainless steel offers a familiar, dependable texture that works well for both casual and formal watches, making it one of the most versatile materials in terms of feel.

Functionality: Durability, Resistance, and Maintenance

When selecting materials for your watch case, it’s not just about looks—functionality plays a key role in ensuring your custom watch performs well under different conditions. The durability, resistance to elements, and ease of maintenance of the material you choose will have a long-term impact on your watch’s lifespan and customer satisfaction.

Durability

The durability of a watch case largely depends on the material’s strength and its ability to withstand daily wear and tear. Stainless steel is a highly durable material, resistant to scratches and dents, making it a solid choice for both luxury and everyday watches. It can handle the rigors of daily use, whether it’s worn at the office or on outdoor adventures.

Titanium is even more durable than stainless steel, known for its toughness and resistance to impact, making it a great option for sport watches or watches designed for rugged environments. Its lightweight properties add to its appeal, allowing for durability without the added weight.

However, when it comes to materials like ceramic, while they offer excellent scratch resistance, they can be more prone to cracking under impact. Gold and other precious metals, although luxurious, are softer and can be scratched more easily. This makes them better suited for dress watches or timepieces designed for special occasions rather than everyday wear.

Resistance to Elements

Certain materials offer better protection against environmental factors like water, heat, and chemicals. Stainless steel is highly resistant to corrosion and oxidation, making it an ideal choice for watches that will be exposed to moisture or worn in various climates. This is why many dive watches or outdoor watches feature stainless steel cases.

Titanium also offers excellent corrosion resistance, but with the added benefit of being hypoallergenic, making it a suitable choice for those with sensitive skin. It’s a top choice for watches designed for harsh conditions, as it can withstand extreme temperatures and resist chemical exposure without corroding or tarnishing.

In contrast, brass and gold can tarnish or discolor over time when exposed to moisture or sweat. Ceramic, while immune to rust or tarnishing, is less resilient to sharp impacts, which can lead to chipping. Understanding these limitations is crucial when designing watches intended for different environments and uses.

Maintenance Requirements

The ease of maintaining a watch case also depends on the material. Stainless steel cases are low-maintenance, needing only occasional polishing to retain their shine, making them a practical choice for customers seeking a fuss-free watch. Titanium is similarly easy to care for, with its naturally matte finish requiring minimal upkeep to maintain its look.

For watches with ceramic cases, care must be taken to avoid dropping or hitting the watch on hard surfaces, but the good news is that ceramic’s scratch-resistant surface stays looking fresh with little maintenance required. Gold and brass, on the other hand, demand more care to avoid scratches or discoloration. These materials may require polishing or regular cleaning to keep their luxurious look intact.

Ultimately, the material you choose for your custom watch will affect not just how your watch looks and feels, but how well it withstands the test of time. By carefully weighing factors like durability, resistance, and maintenance, you can ensure your watch meets the practical needs of your customers without sacrificing design.

Choosing the Right Material for Your Brand

Selecting the perfect material for your custom watch case is a crucial decision that can shape not only the aesthetics and functionality of your timepieces but also your brand’s identity. Each material has its unique strengths and trade-offs, so understanding your brand’s values, target audience, and product positioning is essential when making this choice.

Aligning Material with Brand Identity

The material you choose for your watch case speaks volumes about your brand’s image. For example, if your brand is known for luxury and elegance, using premium materials such as gold, platinum, or rose gold can reinforce that identity, signaling sophistication and exclusivity. These materials naturally align with high-end, limited-edition collections that cater to discerning customers who appreciate luxury craftsmanship.

On the other hand, if your brand focuses on innovation and modern design, materials like ceramic or titanium are excellent options. Ceramic gives watches a cutting-edge, high-tech aesthetic, while titanium combines durability with a sleek, contemporary look, making it ideal for brands targeting younger, trend-focused consumers or active individuals.

Brands that prioritize sustainability might consider materials such as recycled stainless steel or brass, which offer eco-friendly benefits while still providing robust performance. Showcasing environmentally conscious materials not only reflects your brand’s commitment to sustainability but also appeals to today’s environmentally aware consumers.

Considering Your Target Audience

Understanding your target audience is vital when choosing a watch case material. If your customers seek watches for everyday wear, materials like stainless steel or titanium might be ideal due to their durability and ease of maintenance. These materials are practical yet stylish, appealing to a broad range of customers, from professionals to outdoor enthusiasts.

For brands targeting luxury consumers, materials like gold or platinum will cater to their desire for exclusivity and craftsmanship. Customers seeking investment pieces or statement watches are more likely to appreciate these premium materials.

If your brand caters to a younger, fashion-forward audience, you might opt for bold materials such as ceramic or carbon fiber, which offer distinctive looks and align with modern design trends. These materials provide opportunities to create striking, unique watches that stand out in the market.

Balancing Cost and Value

Another key consideration when choosing a material is cost. While materials like gold and platinum add luxury appeal, they come with higher price points. If your goal is to offer affordable luxury, stainless steel provides an excellent balance of quality, durability, and cost-effectiveness. For brands aiming to offer high-end watches without excessive material costs, titanium offers an upscale look and feel without the premium price of precious metals.

Similarly, for brands wanting to differentiate themselves with sustainable materials while keeping production costs reasonable, brass or recycled metals can provide a cost-effective yet environmentally friendly alternative.

Final Thoughts

Choosing the right watch case material ultimately comes down to aligning your material choices with your brand’s identity and values. Whether you prioritize luxury, durability, sustainability, or affordability, the material you select will play a significant role in how customers perceive your brand and products. By making thoughtful choices, you can create custom watches that not only meet functional needs but also resonate deeply with your target audience, strengthening your brand’s position in the market.

Future Trends in Watch Case Materials

As the watch industry evolves, so do the materials used in crafting custom timepieces. Staying ahead of these trends not only positions your brand as forward-thinking but also allows you to offer innovative designs that resonate with changing customer preferences. In recent years, several key trends have emerged in watch case materials, and these are expected to influence the future of watch manufacturing.

Sustainability and Eco-Friendly Materials

One of the most significant trends shaping the future of watchmaking is the growing demand for sustainability. Customers, especially younger generations, are increasingly concerned about the environmental impact of the products they purchase. As a result, many brands are exploring recycled metals, biodegradable materials, and sustainably sourced options to meet this demand.

Recycled stainless steel is already becoming a popular choice, as it retains the durability and sleek aesthetic of traditional steel while reducing the environmental footprint. Other eco-friendly options, such as bio-based plastics or natural materials like wood, are being integrated into case designs for brands that prioritize environmental consciousness.

For brands focused on sustainability, embracing these materials signals a strong commitment to reducing waste and promoting responsible production, aligning with consumer values and market demands.

High-Performance Materials for Active Lifestyles

As watches designed for active or outdoor use continue to grow in popularity, there’s a corresponding demand for high-performance materials that can withstand extreme conditions. Materials such as carbon fiber, ceramic composites, and titanium alloys are being increasingly used in watch case design due to their exceptional strength, lightness, and resistance to both impact and environmental factors.

Carbon fiber is particularly appealing to brands targeting sports enthusiasts, as it combines a lightweight feel with superior durability. Additionally, ceramic composites offer enhanced scratch resistance and heat resistance, making them ideal for outdoor or high-performance timepieces. These materials are pushing the boundaries of what watches can endure while maintaining a sleek, modern appearance.

Advanced Alloys and Hybrid Materials

The future also holds exciting potential for the development of advanced alloys and hybrid materials that offer a mix of benefits. Innovations such as tantalum, liquidmetal, and composite materials blend the best properties of various materials to create watch cases that are both visually striking and highly functional.

Tantalum, for example, is an emerging material that offers excellent corrosion resistance and a unique bluish hue, which appeals to brands looking to create standout designs. Liquidmetal, a patented alloy known for its incredible strength and flexibility, has started to appear in luxury watches, offering a premium look with enhanced durability. Hybrid materials combine different substances like ceramic and metal to achieve a perfect balance between aesthetics and performance, giving brands more design freedom.

Personalization and Customization in Material Selection

With advances in technology, brands are finding new ways to offer personalized material choices to their clients. In the future, we can expect watch manufacturers to offer more bespoke options in terms of case materials, allowing customers to choose not only the shape and finish but also unique materials tailored to their preferences.

3D printing and other modern manufacturing techniques are making it easier for brands to experiment with a wider variety of materials, offering custom case options that blend both traditional and innovative elements. This level of customization allows brands to stand out in a competitive market by offering truly one-of-a-kind designs.

What’s Next for Your Brand?

As these trends continue to shape the watch industry, brands that are quick to embrace innovative materials will stay ahead of the competition. Whether it’s by incorporating sustainable practices, high-performance alloys, or exploring personalized options through cutting-edge technology, the future of custom watch case materials offers limitless possibilities.

By staying informed of these emerging trends, your brand can continue to offer customers the very best in design, functionality, and forward-thinking craftsmanship, ensuring your watches not only meet today’s needs but are also built for tomorrow’s market.

Final Thoughts on Custom Watch Case Materials

When it comes to custom watch manufacturing, the choice of watch case material is far more than a technical decision—it’s a defining aspect of your brand’s identity, design philosophy, and market positioning. The right material has the power to elevate the overall aesthetic of a watch, enhance its durability, and even shape the perception of your brand in the eyes of your target audience.

Finding the Balance Between Form and Function

One of the greatest challenges in selecting a watch case material is finding the right balance between form (the look and feel) and function (the performance and longevity). Whether you’re designing for luxury or practical everyday wear, the material you choose plays a critical role in how your watches are experienced by customers.

High-end materials such as gold, titanium, or platinum create an air of sophistication and durability, while more affordable options like stainless steel or brass provide versatility without compromising quality. Understanding your brand’s needs and your audience’s preferences allows you to make material choices that align with your business goals.

The Importance of Material Innovation

In the ever-evolving world of watchmaking, innovation in materials can set your brand apart. Keeping an eye on emerging materials and trends in the industry not only ensures your products stay relevant but also gives you the edge in offering something new and exciting to the market. For instance, materials like carbon fiber, ceramics, and recycled metals have already made their mark and will continue to offer exciting possibilities for both aesthetic appeal and performance.

Collaborating with an Experienced Manufacturer

Choosing the right partner to bring your custom watch designs to life is equally important. Collaborating with an experienced OEM watch manufacturer can help you navigate the complexities of material selection, from understanding the cost implications to ensuring the material’s compatibility with your overall design. A knowledgeable ODM watch partner will also guide you through the production process, ensuring that your vision is realized with precision and quality.

Whether you’re creating bespoke timepieces for a niche market or developing a broader collection for mass production, selecting the perfect materials for your watch cases is key to ensuring that each piece reflects your brand’s values and craftsmanship.

Your Next Steps

As you continue to explore custom watch manufacturing for your brand, be sure to weigh all the factors we’ve discussed—material aesthetics, functionality, brand alignment, and market trends. By staying informed and making thoughtful choices, you’ll ensure that your watches resonate with your audience and meet the highest standards of design and durability.

For more information on selecting the best materials for your watches, you can explore our watch material options page, where we break down the strengths and applications of each material to help guide your decision-making process.