Custom Watch Manufacturing Process

Create Your Unique Timepiece with Expert Precision

At Romlicen, we understand that every watch tells a story. Our custom watch manufacturing process combines innovative design with exceptional craftsmanship to bring your vision to life. Whether you’re looking for OEM watches, ODM services, or private label options, we guide you through each step, ensuring your unique style and brand identity shine through. Trust us to transform your ideas into exquisite timepieces that stand the test of time.

A Seamless Journey from Concept to Creation

At Romlicen, our custom watch manufacturing process is meticulously designed to ensure every detail aligns with your vision. Here’s a step-by-step overview of how we turn your ideas into reality:

Step 1

Initial Consultation

We begin with a one-on-one consultation to understand your requirements, preferences, and brand identity. This collaborative approach ensures we’re on the same page from the start.

Step 2

Design Development

Our talented designers create a range of design options tailored to your specifications. You’ll receive detailed sketches and digital models to visualize your watch before production.

Step 3

Material Selection

Choose from a variety of premium materials, including stainless steel, leather, and sapphire crystal. We provide guidance on material properties to help you make informed decisions.

Step 4

Manufacturing

Our skilled craftsmen employ advanced techniques to manufacture your watch components with precision. Each piece is made to meet our high standards of quality.

Step 5

Assembly

Each component is meticulously assembled, ensuring that every watch is not only functional but also aesthetically pleasing. Our assembly team pays close attention to detail.

Step 6

Quality Control

Before your watch leaves our facility, it undergoes rigorous quality checks to ensure it meets our exacting standards. We test for accuracy, durability, and overall craftsmanship.

Step 7

Delivery

Once approved, your custom watches are packaged with care and delivered to you. We ensure timely delivery to meet your deadlines.

Transforming Your Vision into a Timeless Masterpiece

At Romlicen, each phase of our manufacturing process is crafted with care and precision.

1. Design Phase

Conceptualization: Turning Ideas into Reality

The design phase is where your vision begins to take shape. At Romlicen, we believe that collaboration is key to creating a unique timepiece that resonates with your brand. Here’s how we approach this crucial step:

- Initial Consultation: Our journey starts with an in-depth consultation. During this session, we discuss your ideas, preferences, and the story you want your watch to convey. Whether you have a clear concept in mind or need inspiration, our team is here to guide you.

- Mood Boards and Inspiration: To better understand your vision, we create mood boards that incorporate design elements, color palettes, and materials that align with your brand. This visual representation serves as a foundation for the design process.

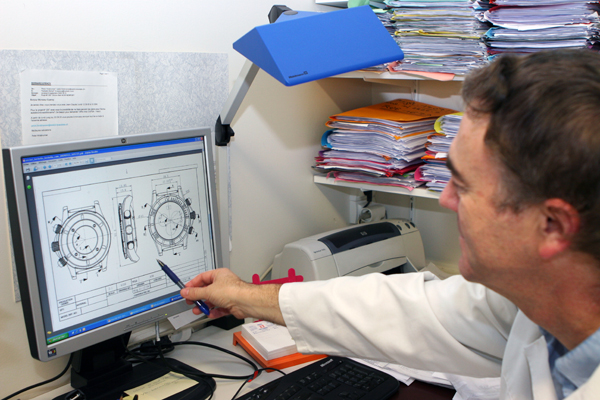

- Sketching and Concept Development: Our talented designers take the insights gained from the consultation and create initial sketches. These sketches capture the essence of your ideas, including case shapes, dial designs, and strap styles.

Digital Prototyping: Visualizing Your Design

Once we have your feedback on the initial sketches, we move on to digital prototyping, which brings your watch design to life in a more detailed format:

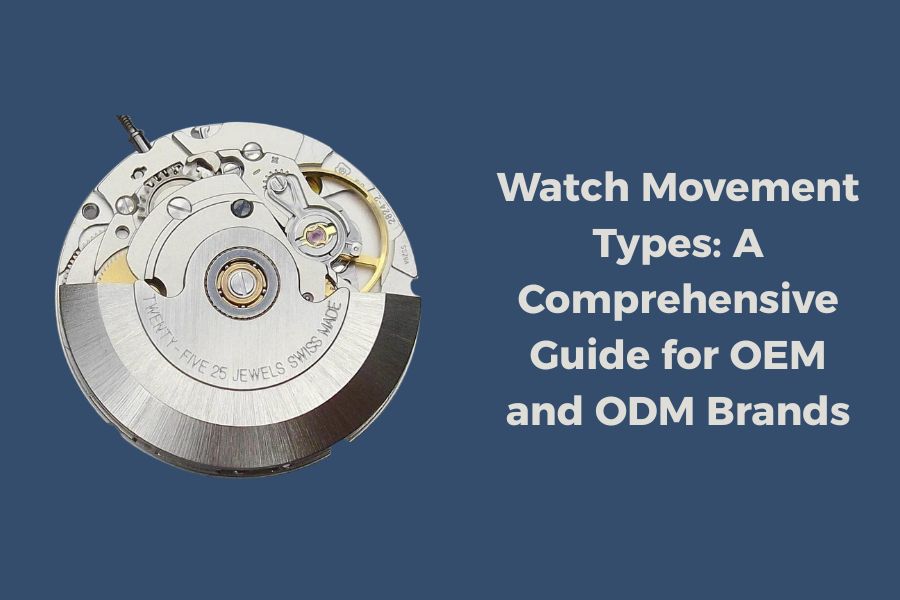

- 3D Modeling: Using advanced CAD (Computer-Aided Design) software, we develop 3D models of your watch. This allows you to see the watch from multiple angles and understand how the components fit together.

- Interactive Visualization: Our digital prototypes can be viewed interactively, enabling you to explore design features such as case thickness, dial markings, and strap attachments. This step ensures that every detail is perfect before moving to production.

- Adjustments and Refinements: Based on your feedback, we make any necessary adjustments to the design. This iterative process ensures that the final product aligns perfectly with your vision, giving you confidence in your choice.

Final Design Approval: The Green Light for Production

After refining the design through collaboration, we reach the final approval stage:

- Presentation of Final Prototype: We present the final digital prototype along with material options and color choices. This allows you to see exactly how your watch will look and feel.

- Approval Process: Once you’re satisfied with the design, we secure your approval to proceed to the next stage. Your satisfaction is our priority, and we want to ensure that you’re excited about the design before manufacturing begins.

2. Material Selection

Choosing the Right Materials for Your Custom Watch

The materials you select play a crucial role in the overall quality, functionality, and aesthetic appeal of your watch. At Romlicen, we offer a wide range of premium materials, ensuring that your custom timepiece is not only beautiful but also durable. Here’s how we guide you through the material selection phase:

Understanding Material Options

- 316L Stainless Steel: Known for its corrosion resistance and durability, 316L stainless steel is a popular choice for watch cases and bracelets. It maintains its luster over time, making it an excellent option for luxury watches.

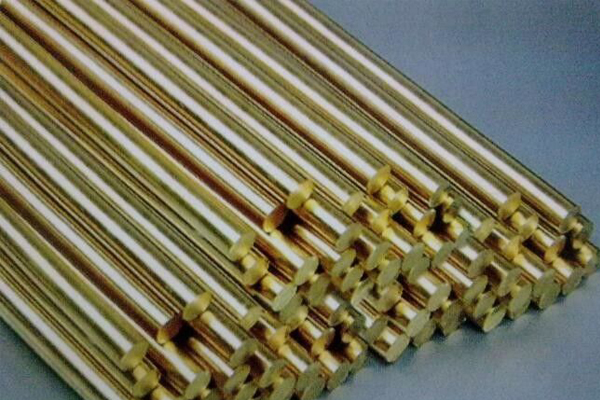

- Brass: Often used for the inner workings of watches, brass provides a robust base for movements and components. Its ability to be easily plated or coated makes it versatile for different designs.

- Titanium: For those seeking a lightweight yet strong option, titanium is an excellent choice. Its natural resistance to scratches and corrosion makes it ideal for outdoor or sport watches.

- Leather: Genuine leather straps offer comfort and elegance. We provide a variety of leather types, including calfskin, ostrich, and exotic leathers, allowing you to choose a texture and finish that suits your brand.

- Sapphire Crystal: Used for watch faces, sapphire crystal is scratch-resistant and highly durable. Its optical clarity ensures that the dial is always easy to read, making it a preferred choice for high-end watches.

Guidance on Material Properties

Understanding the properties of different materials is essential for making informed decisions. Our team provides in-depth insights on each option:

- Durability and Maintenance: We explain how each material stands up to daily wear and tear, as well as any necessary maintenance to keep your watch looking its best.

- Aesthetic Appeal: Different materials lend themselves to various aesthetics. We discuss how the choice of materials can enhance the overall design and feel of your watch, aligning with your brand image.

- Cost Considerations: Material choices can significantly impact the overall cost of your watch. We provide transparent pricing information for different materials, helping you stay within budget while achieving the desired look and functionality.

Finalizing Your Material Choices

- Sample Viewing: To aid your decision-making, we provide samples of materials for you to touch and see. This tactile experience allows you to appreciate the quality and appearance of each option.

- Expert Recommendations: Based on your design and functional requirements, our team offers personalized recommendations, ensuring that the materials selected align perfectly with your vision.

- Approval Process: Once you’ve made your selections, we confirm your choices before moving on to the manufacturing stage. Your satisfaction with the materials is crucial to the success of your custom watch.

3. Manufacturing

Precision Engineering: Crafting Your Vision into Reality

The manufacturing phase is where your custom watch truly begins to take form. At Romlicen, we employ advanced technology and skilled craftsmanship to ensure every component is produced to the highest standards. Here’s how we approach the manufacturing process:

Advanced Machinery and Techniques

- State-of-the-Art Equipment: We utilize cutting-edge machinery for precision machining, ensuring that each component is crafted with exacting standards. Our equipment includes CNC machines, which allow for intricate designs and precise cuts, as well as automated assembly lines for efficiency.

- Quality Materials Handling: Throughout the manufacturing process, we handle materials with care to maintain their integrity. Our team is trained to minimize waste and ensure that only the best components are used in your watch.

Custom Component Creation

- Case Production: The watch case is the foundation of your timepiece. We start by crafting the case according to your specifications, whether you prefer a sleek, minimalist design or a more robust, sporty look. Each case is produced with attention to detail, ensuring it aligns with your vision.

- Dial Manufacturing: The dial is where your brand truly shines. We work closely with you to design the dial layout, including markers, hands, and any custom logos or text. Our printing techniques ensure clarity and durability, so your brand stands out.

- Movement Assembly: If you’re opting for an automatic or quartz movement, our expert technicians carefully assemble the movement inside the case. We source movements from reputable brands, ensuring reliability and accuracy in timekeeping.

- Strap Production: Our customization extends to the watch strap, where you can choose from various materials and styles. Whether it’s leather, metal, or a unique synthetic material, each strap is produced to complement the overall design of your watch.

Quality Assurance During Manufacturing

- Continuous Monitoring: Throughout the manufacturing process, we implement rigorous quality control measures. Our team continuously monitors each stage to ensure that every component meets our high standards.

- Prototype Validation: Before full-scale production, we create a prototype of your watch. This prototype undergoes extensive testing for functionality, durability, and aesthetic appeal. Your feedback on the prototype allows us to make any necessary adjustments before final production.

- Commitment to Excellence: Our goal is to produce watches that not only meet but exceed your expectations. We believe that the quality of our manufacturing process directly impacts your brand’s reputation, so we remain dedicated to excellence at every step.

4. Assembly and Quality Control

Crafting Perfection: Assembling Your Custom Watch

The assembly phase is where all the meticulously crafted components come together to create your final watch. At Romlicen, we prioritize precision and attention to detail to ensure that every watch not only looks beautiful but also functions flawlessly. Here’s how we handle this crucial stage:

Careful Assembly Process

- Component Integration: Our skilled technicians carefully integrate all watch components, including the case, dial, movement, and strap. This process requires a steady hand and keen eye for detail to ensure that each piece fits perfectly and operates smoothly.

- Movement Calibration: Once assembled, we calibrate the watch movement for accuracy. Our experts fine-tune the mechanism to ensure precise timekeeping, which is essential for delivering a reliable product to your customers.

- Final Touches: After assembly, we add any finishing touches, such as polishing the case and strap, ensuring that every surface shines and reflects the quality of craftsmanship that defines your brand.

Rigorous Quality Control Measures

- Comprehensive Testing: Every watch undergoes a series of rigorous tests to assess its performance and durability. These tests include water resistance checks, impact resistance evaluations, and timekeeping accuracy assessments, ensuring that your watch meets the highest industry standards.

- Visual Inspections: Our quality control team conducts thorough visual inspections at various stages of the assembly process. This includes checking for any aesthetic imperfections, such as scratches or misalignments, to ensure that the final product is flawless.

- Documentation and Reporting: Each watch is documented throughout the quality control process, providing a traceable record of tests conducted and results achieved. This transparency reinforces our commitment to quality and allows us to address any issues proactively.

Final Approval Before Shipment

- Client Review: Before shipping your order, we invite you to review the final products. This step ensures that you are completely satisfied with the quality and craftsmanship of your custom watches. Your feedback is invaluable, and we want to ensure that every detail aligns with your expectations.

- Packaging and Presentation: Once approved, your watches are carefully packaged to prevent any damage during transit. We pay special attention to the presentation, ensuring that your brand’s image is reflected in the packaging.

- Timely Delivery: With everything in place, we prepare for timely delivery. We understand the importance of meeting deadlines, and our efficient logistics team works to ensure your watches arrive when you need them.

Post-Production Services

Ensuring Lasting Quality and Support for Your Custom Watch

At Romlicen, our commitment to your satisfaction doesn’t end with the completion of your custom watch. Our post-production services are designed to provide you with ongoing support, ensuring that your product maintains its quality and your brand continues to thrive. Here’s how we assist you after production:

1. Packaging and Branding

Elevating Your Brand’s Presence

Custom Packaging Solutions: We understand the importance of first impressions. Our custom packaging options are designed to reflect your brand identity and enhance the unboxing experience. Whether you prefer elegant boxes or eco-friendly solutions, we offer packaging that resonates with your brand values.

Branding Materials: In addition to packaging, we provide branding materials such as certificates of authenticity, care instructions, and promotional inserts. These materials not only educate your customers but also reinforce your brand image.

2. Warranty and Support

Building Trust with Your Customers

Comprehensive Warranty: We offer a warranty on all our custom watches, covering defects in materials and workmanship. This commitment to quality gives you and your customers peace of mind, knowing that we stand behind our products.

Customer Support: Our dedicated customer support team is available to assist you and your customers with any inquiries or concerns. Whether it’s troubleshooting, maintenance tips, or warranty claims, we’re here to help.

3. Maintenance and Repair Services

Ensuring Longevity for Your Custom Watch

Regular Maintenance Recommendations: To keep your watches in optimal condition, we provide guidelines for regular maintenance. This includes advice on cleaning, battery replacement, and servicing to ensure longevity.

Repair Services: In the event of damage or wear, we offer repair services to restore your watch to its original condition. Our skilled technicians use high-quality parts to ensure the watch performs as intended.

4. Marketing Support

Helping You Promote Your Brand

Marketing Materials: To aid in your marketing efforts, we can provide digital assets, including high-resolution images and videos of your custom watches. These materials can be used for online marketing, social media promotion, and other advertising channels.

Collaborative Marketing Strategies: We believe in a partnership approach. Our team can work with you to develop effective marketing strategies that resonate with your target audience and showcase the unique features of your watches.

Partnering for Success: Your Vision, Our Expertise

At Romlicen, we believe that effective collaboration and open communication are key to creating custom watches that truly reflect your brand vision. Our client-centric approach ensures that you are involved in every step of the process, from concept to final product. Here’s how we prioritize your collaboration and communication throughout our partnership:

1. Initial Consultation

Understanding Your Needs

Comprehensive Needs Assessment: Our journey begins with a detailed consultation where we listen to your ideas and requirements. We discuss your brand identity, design preferences, and specific features you want in your custom watch.

Expert Guidance: Our team of watch manufacturing experts is available to provide insights and recommendations. Whether you need advice on design elements, materials, or movements, we are here to guide you in making informed decisions.

2. Regular Updates and Feedback Loops

Keeping You Informed

Scheduled Progress Updates: Throughout the manufacturing process, we provide regular updates on the status of your project. These updates include timelines, milestones achieved, and any challenges encountered, ensuring you are always in the loop.

Feedback Opportunities: We value your input and encourage feedback at every stage. Whether it’s reviewing design drafts or assessing prototypes, your insights are crucial to achieving the final product you envision.

3. Transparent Communication Channels

Accessibility and Clarity

Dedicated Account Manager: Each client is assigned a dedicated account manager who serves as your primary point of contact. This ensures that you have a knowledgeable partner readily available to address any questions or concerns.

Open Communication Platforms: We utilize various communication tools, including email, phone calls, and video conferences, to facilitate seamless interactions. Our goal is to ensure that you feel supported and informed throughout the manufacturing journey.

4. Final Review and Approval

Ensuring Your Satisfaction

Pre-Production Review: Before moving into full-scale production, we conduct a final review with you. This step includes verifying all design elements, materials, and specifications to ensure everything aligns with your expectations.

Approval Process: We require your formal approval before proceeding. This commitment to transparency guarantees that you have full confidence in the final product before it is manufactured.

5. Post-Production Feedback

Continuous Improvement

Request for Feedback: After delivering your custom watches, we actively seek your feedback on the overall experience. Your insights help us improve our processes and better serve future clients.

Long-Term Relationship: We aim to foster lasting partnerships. Our commitment to communication extends beyond the project’s completion, as we look forward to supporting your future watch manufacturing needs.

Frequently Asked Questions (FAQ)

Your Questions Answered

At Romlicen, we understand that you may have questions about our custom watch manufacturing process. Below are some frequently asked questions that can provide you with valuable insights. If you have additional questions, feel free to reach out to us or visit our dedicated FAQ page.

We typically have a minimum order quantity of 300 for custom watch manufacturing. However, we can discuss your specific needs during the consultation.

The manufacturing process timeline can vary depending on the complexity of the design and the quantity ordered. On average, it takes about 60 days from the initial consultation to final delivery.

Absolutely! We encourage feedback and allow for design adjustments at various stages to ensure the final product meets your expectations.

We offer a wide range of movement options, including Swiss, Japanese, and Chinese movements. During the consultation, we can help you select the best movement for your watch based on your requirements.

Yes, all our custom watches come with a warranty covering defects in materials and workmanship. Our customer support team is available to assist you with any inquiries or issues after purchase.

Getting started is simple! Just reach out to us through our contact form, and we’ll schedule an initial consultation to discuss your vision.

Let’s Create Your Custom Watch Together!

Ready to Bring Your Watch Vision to Life?

At Romlicen, we are dedicated to providing exceptional custom watch manufacturing services tailored to your brand’s needs. With our expertise and your vision, we can create a timepiece that stands out in the market.

Contact Us Today!

Don’t hesitate to reach out to our team to start your journey in creating your unique watch brand. Fill out our contact form, and we’ll get back to you promptly to schedule your initial consultation. Let’s collaborate to make your vision a reality!